LOW INVESTMENT HIGH INCOME

LOW INVESTMENT HIGH INCOME

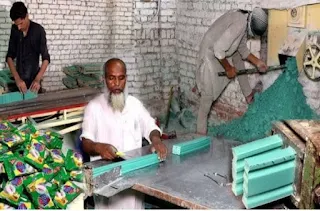

Dishwashing Cake Soap Manufacturing in a Small Space

Dishwashing cake soap is a solid form of detergent used for cleaning dishes, utensils, and kitchenware. It is economical, efficient, and easy to produce, making it an ideal product for small-scale manufacturing. This guide provides a detailed blueprint for setting up a low-cost dishwashing cake soap manufacturing unit, covering materials, equipment, production processes, and cost analysis.

Understanding Dishwashing Cake Soap

Dishwashing cake soap is a solid soap formulated to cut through grease, remove food residues, and clean dishes effectively. It is typically made from a combination of fatty acids, alkalis, and other cleaning agents, molded into solid bars or cakes.

Key Features:

Economical and long-lasting

Effective at cutting grease and grime

Compact and easy to store

Minimal environmental impact compared to liquid soaps

Raw Materials Required

1. Fatty Acids:

Palm Oil/ Coconut Oil: Commonly used for their cleaning properties and lathering capabilities.

Cost: ₹100 - ₹120 per kg

2. Alkalis:

Caustic Soda (Sodium Hydroxide): Used for saponification, turning oils into soap.

Cost: ₹50 - ₹60 per kg

3. Fillers and Additives:

Sodium Silicate: Adds durability and improves cleaning efficiency.

Cost: ₹40 - ₹50 per kg

Sodium Carbonate (Washing Soda): Softens water and enhances cleaning power.

Cost: ₹20 - ₹30 per kg

4. Fragrances and Colorants:

Essential oils or synthetic fragrances for scent.

Food-grade colorants for aesthetic appeal.

Cost: ₹500 - ₹700 per kg (fragrance)

Cost: ₹200 - ₹300 per kg (colorant)

5. Water:

Used as a solvent and to aid in the saponification process.

Cost: Negligible (assuming access to clean water)

Estimated Material Costs (Per 100 kg Batch):

Palm Oil/Coconut Oil: ₹10,000 - ₹12,000

Caustic Soda: ₹5,000 - ₹6,000

Sodium Silicate: ₹4,000 - ₹5,000

Sodium Carbonate: ₹2,000 - ₹3,000

Fragrance: ₹500 - ₹700

Colorant: ₹200 - ₹300

Water: ₹30

Total Material Cost: ₹21,700 - ₹26,000

Equipment Needed

1. Mixing Tank:

Stainless steel or HDPE tank for mixing raw materials.

Cost: ₹10,000 - ₹15,000

2. Stirrer/Blender:

For thorough mixing and ensuring uniform consistency.

Cost: ₹5,000 - ₹10,000

3. Heating Equipment:

Electric or gas heating system to maintain required temperatures during saponification.

Cost: ₹5,000 - ₹8,000

4. Soap Molds:

Molds to shape the soap into cakes.

Cost: ₹3,000 - ₹5,000 (for multiple molds)

5. Cutting Tools:

Manual or automatic cutting tools for slicing the soap into cakes.

Cost: ₹3,000 - ₹6,000

6. Packaging Equipment:

Basic equipment for wrapping and labeling the soap.

Cost: ₹2,000 - ₹4,000

7. Protective Gear:

Gloves, goggles, and aprons for safety during production.

Cost: ₹500

Estimated Equipment Costs:

Total Equipment Cost: ₹28,500 - ₹48,500

Production Process

1. Preparation:

Clean and sanitize the workspace.

Measure all ingredients accurately.

2. Saponification:

Heat the palm oil or coconut oil in the mixing tank to the desired temperature (around 70°C).

Slowly add caustic soda dissolved in water, stirring continuously to initiate saponification.

3. Incorporating Additives:

Add sodium silicate and sodium carbonate to the mixture, continuing to stir.

Introduce fragrances and colorants, ensuring even distribution.

4. Molding and Cooling:

Pour the soap mixture into molds and allow it to set and cool.

This process may take several hours to ensure the soap solidifies properly.

5. Cutting and Curing:

Once the soap is solid, remove it from the molds and cut it into uniform cakes.

Allow the soap cakes to cure for 2-4 weeks to achieve optimal hardness and durability.

6. Packaging:

Wrap each soap cake in plastic or paper and label them appropriately.

Quality Control

1. pH Testing:

Ensure the final product has a pH between 7 and 10, suitable for cleaning yet gentle on skin.

2. Hardness Testing:

Check the soap's firmness to ensure it will last through multiple uses.

3. Performance Testing:

Test the soap on greasy dishes to assess its cleaning efficiency.

4. Stability Testing:

Store samples under different conditions to evaluate shelf stability.

Cost Analysis and Profitability

1. Material Costs (Per 100 kg Batch): ₹21,700 - ₹26,000

2. Labor Costs: ₹3,000 (assuming ₹200 per hour for 15 hours)

3. Utility Costs: ₹1,500 (electricity, water, heating)

4. Packaging Costs: ₹1,500 (for 1000 units)

5. Total Production Cost: ₹27,700 - ₹32,000

Cost Per Soap Cake (100 grams):

Total Production Cost: ₹27,700 - ₹32,000

Cost Per Cake: ₹2.77 - ₹3.20

Selling Price:

Assuming a selling price of ₹5 per cake, the profit per unit would be ₹1.80 - ₹2.23.

Monthly production of 10,000 cakes could yield a profit of ₹18,000 - ₹22,300.

Marketing and Distribution

1. Target Market:

Households, small businesses, and retailers in urban and rural areas.

2. Marketing Strategy:

Utilize local advertising, social media, and direct sales to reach customers.

Highlight the affordability and effectiveness of the product.

3. Distribution Channels:

Distribute through local grocery stores, supermarkets, and online platforms.

Chapter 8: Scaling Up

1. Increasing Production Capacity:

Invest in larger mixing tanks, automated molding, and cutting equipment.

2. Diversifying Product Range:

Introduce variants such as scented, antibacterial, or eco-friendly soap cakes.

3. Quality Assurance:

Implement rigorous quality control processes to maintain high product standards.

Manufacturing dishwashing cake soap at a low cost in a small space is a viable and profitable venture. With a modest investment in materials and equipment, combined with effective marketing and distribution strategies, you can establish a successful business catering to the demand for economical and efficient cleaning products. By focusing on quality, efficiency, and customer satisfaction, you can scale your operations and expand your market reach over time.

Comments

Post a Comment